Temperature-Controlled OPL Series

High quality sealing with the ideal heat condition

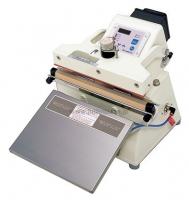

OPL-300-5

Model Lineup

OPL-200-10

OPL-300-5

OPL-450-5

OPL-600-5

Main Features

| Applications & Features | Semi-auto sealer with temperature control |

| Operating method | Electric |

| Packaging type | Seal only |

| Daily use frequency as model selection guideline | Up to 3,000 bags, electric |

| Bag size (max.) | 20, 30, 45, 60cm / 8, 12, 17.7, 23.6 inches |

| Latest type | Type J |

Compatible packaging materials (total thickness of two or more sheets):

- PE : 0.4mm/15.7mil

- PP : 0.3mm/11.8mil,

- NY : 0.3mm/11.8mil,

- PVA : 0.3mm/11.8mil,

- Other laminated materials : 0.4mm/15.7mil

Overview of OPL series

The OPL series is a table-top impulse sealer standard equipped with the ONPUL temperature controlling system developed by Fuji Impulse.

The OPL series sealer has four different sealing lengths in its lineup, enabling a wide variety of usage.

Temperature control using temperature sensor

ONPUL

The OPL series is a table-top impulse sealer standard equipped with the ONPUL temperature controlling system developed by Fuji Impulse. The OPL series sealer has four different sealing lengths in its lineup, enabling a wide variety of usage.

Ideal sealing condition

With the ONPUL System, a user can set the heating temperature to the temperature at which a film melts. This means that the user can increase the sealing strength. In addition, because only the required energy is used in the seal heating and cooling processes, it saves energy and increases work efficiency, as well as extend the product life of parts such as the heating element, Teflon sheet and glass tape.

Simple operation

Use the touch panel on the control unit to set conditions such as the heating temperature. To set the settings, use the Mode Switch. After setting the appropriate sealing condition for the packaging material, select either automatic continuous operation or manual air-pedal operation. The OPL-200 and OPL-300 series of sealers also offer a selection of different methods with which to press the table switch plate.

If a table is required for the OPL-450 and OPL-600 series of sealers, use the FA stand combined with a special table.

When using the table-switch plate, set the air pedal under the table-switch plate. The OPL-200 and OPL-300 series of sealers are shipped with the air pedal set under the table-switch plate.

Good for a variety of packaging materials

The following model variations are available:Good for seal lengths of 200, 300, 450 and 600mm . as well as for seal widths of 5 and 10 mm .

Available only as a single heater type capable of sealing materials up to 0.3mm thick (total thickness of overlapping sheets).

Sealing an oxygen scavenger inside a gas-barrier material packaging can help extend a product life.

Table-switch plate

Users of the OPL-200 and OPL-300 series of sealers may use the attached table-switch plate instead of the operation-start switch. The applied pressure may be adjusted according to the weight of the package content. When using the table-switch plate, set the air pedal under the table-switch plate.

Options

Table (optional): Choose a table for your work environment

We offer various tables as option based on your environment and model. While we do provide the best table for general expected settings for each model, optional tables are available in cases the standard item does not match your needs.

1. Standard table: This is a stainless, single-leaf table that attaches to the seal frame. There is no "600 standard table" as a standard table cannot be installed on a 600mm sealer.

2. Special Table: The Special Table attaches to the support pipe of the optional FA stand. It can support the weight of a heavy package. Height can be adjusted within the range of the support pipe. (See photo on this page explaining the FA stand) If a table is required for the OPL-450 and OPL-600 series of sealers, use the FA stand combined with a special table.

| Name | Dimension |

| For 200&300 Table-switch plate | 280(11") × 210(8.3") |

| 200Standard table | 200(7.8") × 150(5.9") |

| 300Standard table | 300(11.8") × 150(5.9") |

| 450Standard table | 400(15.7") × 150(5.9") |

| 600Special table | 600(23.6") × 190(7.5") |

| 300 / 450Special table | 450(17.7") × 190(7.5") |